Can Solar Power Melt Steel?

Written by: Briain Kelly

Published: June 10, 2024

Last updated: October 19, 2025

Reading time: 4 mins

When we think of the sun the first things that come to mind are light, fire, and heat. With that in mind, it might be strange to consider that when we make use of the sun, it’s mostly for producing electricity rather than finding some way to take advantage of that heat.

Solar panels of course produce electricity through the photovoltaic effect. This is caused by energetic electrons rather than a heat based power. In fact, excessive heat is bad for the efficiency of solar panels.

That isn’t to say that there is no use for the heat of the sun. Long before solar electricity was a gleam in the imagination of US inventor Charles Fritt in the 19th century people were using mirrors and lenses to concentrate heat for practical purposes.

And why not, it’s free energy, a relatively easy way to start fires and even cook food.

So just how powerful can the concentrated power of the sun get? Or to ask the question you already read in the title, can solar power melt steel?

Short answer, yes. Anticlimactic I know but that doesn’t make it any less impressive. Steel, an alloy of iron and carbon, has a melting point of anywhere between 1,350℃ – 1,550℃. Reaching that kind of temperature using just the natural power of the sun requires some hefty construction.

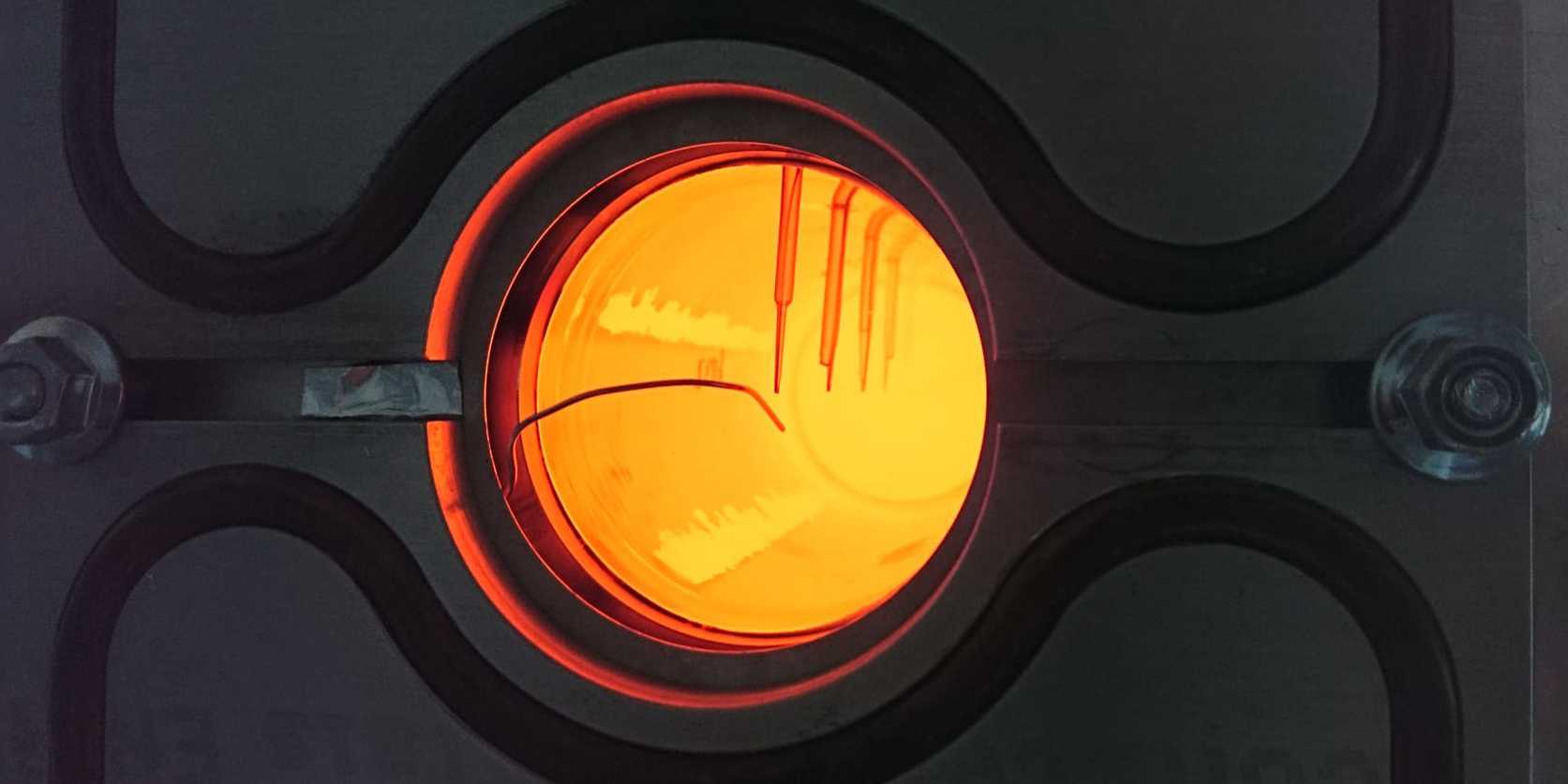

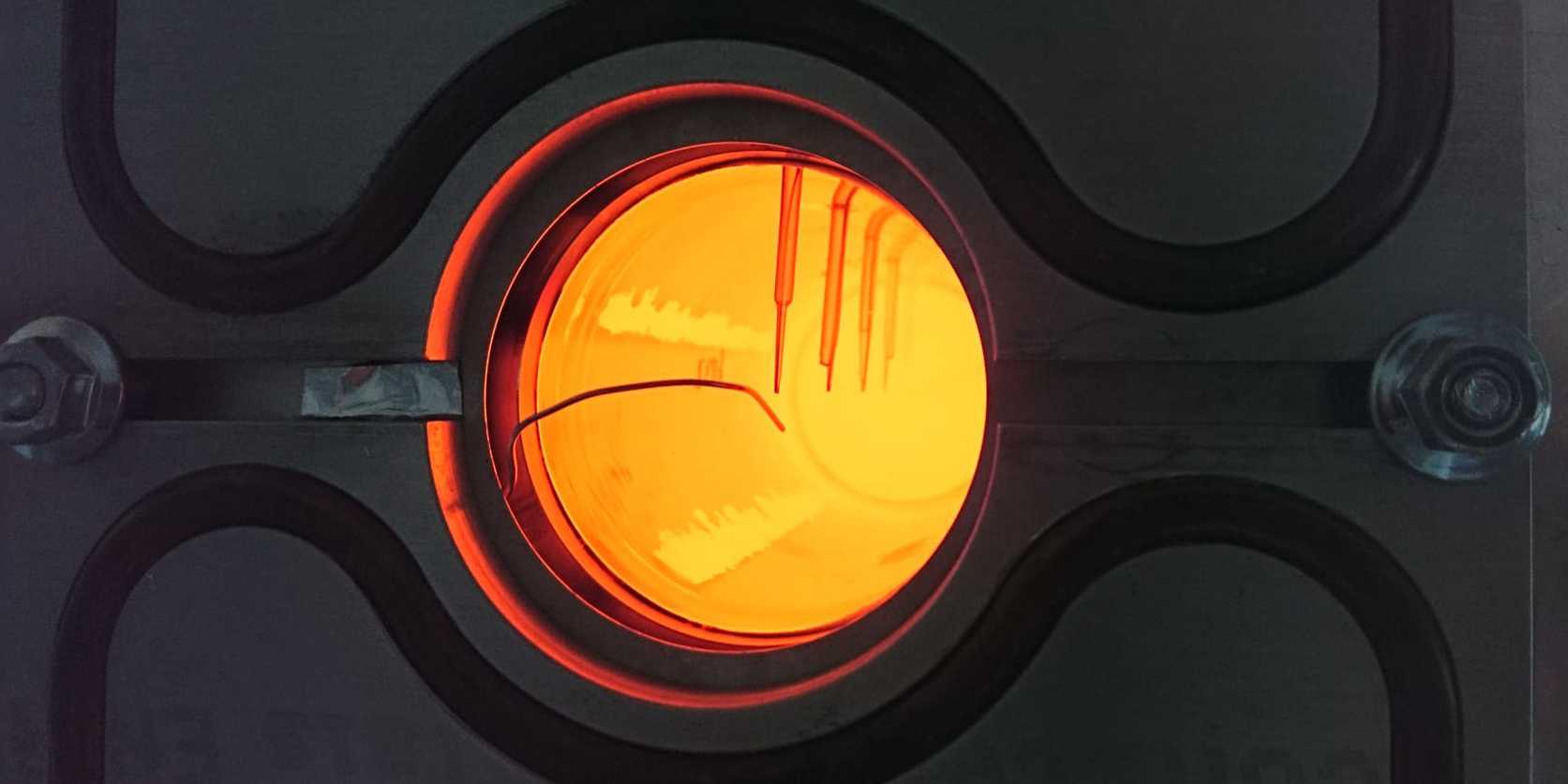

A Solar Furnace is the name given to an array of mirrors designed to focus an immense amount of sunlight onto a small area. I’m sure everyone has at least heard of using a magnifying glass to set paper on fire, but a solar furnace is many orders of magnitude greater than that in the amount of light it can focus.

Temperatures ranging from hundreds to thousands of degrees celsius are possible depending on the location and the size of the mirror array.

What’s so Important about Solar Heat

There are many industrial processes which require intense heat to function properly. Not least of those is producing metal, either by smelting ore or by recycling existing metal.

Other process heat systems include separating components in crude oil during the refining process, food processing, or automobile paint drying.

The majority of these processes still require fossil fuel systems, burning an intense amount of energy to produce raw materials. Some estimates put 30% – 40% of the cost of manufactured steel in the energy requirements to make it.

Using renewable and green solar energy for industrial applications has the potential to save companies significant amounts of money, and help with a greener future.

Solar furnaces typically require large scale setups to achieve the kind of heat which is required for industrial applications, so there is a lot of progress which still needs to be made on that front. But back to the melty part of the show.

Harnessing the Power of the Sun

There are multiple high powered solar furnaces currently used by research institutes around the world for conducting experiments on different materials.

As an observer it seems as though the only possible experiment to conduct is ‘does it melt or not?’, but I’m sure it’s more complicated than that.

The National Renewable Energy Laboratory in the United States operates a High-Flux Solar Furnace at its Mountain Table South.

There, its 10kW output can reach up to 1,800℃ in standard operating conditions, more than capable of melting steel or screwing up the cast iron pan your house mate would not stop waxing lyrical about with its 1,127-1,204℃ meeting point.

The largest and most powerful solar furnace in the world is located at Font-Romeu-Odeillo-Via, France where the National Centre for Scientific Research (CNRS) conducts materials research on elements by exposing them to extremely high temperatures.

Becoming operational in 1969, the Odeillo Solar Furnace forms a parabolic lens 48m high and 54m wide, made from almost 10,000 mirrors. This concentrates the power of thousands of suns into an area just 40cm across.

The Odeillo solar furnace can reach staggering temperatures of up to 3,500℃, hot enough that it’s used to test things like what would happen to materials during atmospheric reentry, or when they’re around the kind of temperatures produced by ‘nuclear devices’.

Of course, this isn’t exactly practical for industrial purposes since it’s the size of a building and focuses heat into a very small area.

I’m sure it makes for some spectacular shows when it heats up to thousands of degrees in a matter of seconds until metal runs like butter. However, efficiency in technology has always been about making things smaller, while just as effective.

Nonetheless, those clever folks at the CNRS have also lent their expertise in harnessing the power of the sun for more mundane tasks, namely the recycling of metal.

Solar Heat for Metal Manufacturing

So now that we’re talking about talking about industrial scale metal smithing with the burning power of the sun, it’s pretty obvious where this is going next. That’s right. Watches.

No really. Swiss company Panatere has committed to making itself 100% sustainable by using recycled metal manufactured with renewable energy.

It makes a lot of sense when you look at the manufacturing processes. Making high-precision microcomponents is naturally going to produce a lot of waste material which is still high-quality steel or other valuable metals.

Rather than transporting expensive materials from elsewhere, it is simpler to look at recycling locally sourced metals.

Having first been announced in 2022 the project has faced multiple setbacks but is expected to get up and running in 2024.

When completed the recycling facility will feature two 15m wide and 6m high solar ovens reaching up to 2,000℃, hot enough to recycle both steel and titanium offcuts and waste back into raw materials.

The company is planning to keep the two solar ovens operating for a two-year trial period to assess their efficiency before making any further planning.

In what could potentially be a breakthrough in making the technology less bulky, researchers at ETH Zurich recently developed a thermal trap which can reach temperatures of over 1,000℃ with a much smaller setup.

The thermal trap they built consists of a quartz rod 7.5 centimetres in diameter and 30 centimetres in length tied to a ceramic absorber. One of the goals of the experiment was to improve on the efficiency of solar thermal traps in order to devise something that might be economically viable.

While this was built as a lab experiment rather than a practical device, it was able to achieve temperatures of up to 1,050℃ using light with an intensity equivalent to 135 times that of sunlight. This is far less than other solar furnaces which rely on light with an irradiance of thousands of suns.

A major feature of the design of this solar thermal trap is that it minimises heat loss from radiation, which had been a major limiting factor in reaching temperatures over 600℃ in similar sized systems.

Conclusion

So, answering that first question, yes solar power can melt steel, and it’s something we’re going to be seeing a lot more of. Beyond the simple cool factor adapting solar thermal technologies to decarbonise industry is a must to reduce fossil fuel usage globally.

Can Solar Power Melt Steel?

Published: June 10, 2024

Last updated: October 19, 2025

Written by: Briain Kelly

Reading time: 4mins

When we think of the sun the first things that come to mind are light, fire, and heat. With that in mind, it might be strange to consider that when we make use of the sun, it’s mostly for producing electricity rather than finding some way to take advantage of that heat.

Solar panels of course produce electricity through the photovoltaic effect. This is caused by energetic electrons rather than a heat based power. In fact, excessive heat is bad for the efficiency of solar panels.

That isn’t to say that there is no use for the heat of the sun. Long before solar electricity was a gleam in the imagination of US inventor Charles Fritt in the 19th century people were using mirrors and lenses to concentrate heat for practical purposes.

And why not, it’s free energy, a relatively easy way to start fires and even cook food.

So just how powerful can the concentrated power of the sun get? Or to ask the question you already read in the title, can solar power melt steel?

Short answer, yes. Anticlimactic I know but that doesn’t make it any less impressive. Steel, an alloy of iron and carbon, has a melting point of anywhere between 1,350℃ – 1,550℃. Reaching that kind of temperature using just the natural power of the sun requires some hefty construction.

A Solar Furnace is the name given to an array of mirrors designed to focus an immense amount of sunlight onto a small area. I’m sure everyone has at least heard of using a magnifying glass to set paper on fire, but a solar furnace is many orders of magnitude greater than that in the amount of light it can focus.

Temperatures ranging from hundreds to thousands of degrees celsius are possible depending on the location and the size of the mirror array.

What’s so Important about Solar Heat

There are many industrial processes which require intense heat to function properly. Not least of those is producing metal, either by smelting ore or by recycling existing metal.

Other process heat systems include separating components in crude oil during the refining process, food processing, or automobile paint drying.

The majority of these processes still require fossil fuel systems, burning an intense amount of energy to produce raw materials. Some estimates put 30% – 40% of the cost of manufactured steel in the energy requirements to make it.

Using renewable and green solar energy for industrial applications has the potential to save companies significant amounts of money, and help with a greener future.

Solar furnaces typically require large scale setups to achieve the kind of heat which is required for industrial applications, so there is a lot of progress which still needs to be made on that front. But back to the melty part of the show.

Harnessing the Power of the Sun

There are multiple high powered solar furnaces currently used by research institutes around the world for conducting experiments on different materials.

As an observer it seems as though the only possible experiment to conduct is ‘does it melt or not?’, but I’m sure it’s more complicated than that.

The National Renewable Energy Laboratory in the United States operates a High-Flux Solar Furnace at its Mountain Table South.

There, its 10kW output can reach up to 1,800℃ in standard operating conditions, more than capable of melting steel or screwing up the cast iron pan your house mate would not stop waxing lyrical about with its 1,127-1,204℃ meeting point.

The largest and most powerful solar furnace in the world is located at Font-Romeu-Odeillo-Via, France where the National Centre for Scientific Research (CNRS) conducts materials research on elements by exposing them to extremely high temperatures.

Becoming operational in 1969, the Odeillo Solar Furnace forms a parabolic lens 48m high and 54m wide, made from almost 10,000 mirrors. This concentrates the power of thousands of suns into an area just 40cm across.

The Odeillo solar furnace can reach staggering temperatures of up to 3,500℃, hot enough that it’s used to test things like what would happen to materials during atmospheric reentry, or when they’re around the kind of temperatures produced by ‘nuclear devices’.

Of course, this isn’t exactly practical for industrial purposes since it’s the size of a building and focuses heat into a very small area.

I’m sure it makes for some spectacular shows when it heats up to thousands of degrees in a matter of seconds until metal runs like butter. However, efficiency in technology has always been about making things smaller, while just as effective.

Nonetheless, those clever folks at the CNRS have also lent their expertise in harnessing the power of the sun for more mundane tasks, namely the recycling of metal.

Solar Heat for Metal Manufacturing

So now that we’re talking about talking about industrial scale metal smithing with the burning power of the sun, it’s pretty obvious where this is going next. That’s right. Watches.

No really. Swiss company Panatere has committed to making itself 100% sustainable by using recycled metal manufactured with renewable energy.

It makes a lot of sense when you look at the manufacturing processes. Making high-precision microcomponents is naturally going to produce a lot of waste material which is still high-quality steel or other valuable metals.

Rather than transporting expensive materials from elsewhere, it is simpler to look at recycling locally sourced metals.

Having first been announced in 2022 the project has faced multiple setbacks but is expected to get up and running in 2024.

When completed the recycling facility will feature two 15m wide and 6m high solar ovens reaching up to 2,000℃, hot enough to recycle both steel and titanium offcuts and waste back into raw materials.

The company is planning to keep the two solar ovens operating for a two-year trial period to assess their efficiency before making any further planning.

In what could potentially be a breakthrough in making the technology less bulky, researchers at ETH Zurich recently developed a thermal trap which can reach temperatures of over 1,000℃ with a much smaller setup.

The thermal trap they built consists of a quartz rod 7.5 centimetres in diameter and 30 centimetres in length tied to a ceramic absorber. One of the goals of the experiment was to improve on the efficiency of solar thermal traps in order to devise something that might be economically viable.

While this was built as a lab experiment rather than a practical device, it was able to achieve temperatures of up to 1,050℃ using light with an intensity equivalent to 135 times that of sunlight. This is far less than other solar furnaces which rely on light with an irradiance of thousands of suns.

A major feature of the design of this solar thermal trap is that it minimises heat loss from radiation, which had been a major limiting factor in reaching temperatures over 600℃ in similar sized systems.

Conclusion

So, answering that first question, yes solar power can melt steel, and it’s something we’re going to be seeing a lot more of. Beyond the simple cool factor adapting solar thermal technologies to decarbonise industry is a must to reduce fossil fuel usage globally.

Solar Energy Saves Households Thousands in Electricity Costs

Take our 2-minute questionnaire and find affordable solar options to suit your budget and lifestyle.