A boiler is the primary component of any property’s central heating or hot water system, and gas boilers remain one of the most common types in Ireland.

A boiler can be found in almost all homes and businesses in the country, and for many people, it may be time to upgrade to take advantage of more energy-efficient developments.

Table of Content

What is a Gas Boiler

A Gas Boiler is essentially a furnace, using gas as its fuel source, to create heat and hot water for your home or business. The thermostat controls the boiler and its two primary functions, central heating and hot water production.

How Does a Gas Boiler Work

Gas boilers work fairly simply. Gas is brought into the boiler, either from the mains of an LPG tank, and burned in the combustion chamber in order to heat water.

This fuels either the closed loop of the central heating system, where the hot water is pumped away from the boiler into the radiator, and returns as it cools, or creating hot water for taps in the home.

What happens with that heated water depends on the type of system you have. A Conventional Boiler will send it to a hot water tank for storage, while a Combi Boiler pipes hot water directly to taps.

The boiler is controlled by the thermostat which is used to determine whether the central heating or hot water is on, as well as controlling the preferred temperature.

Gas Boiler Components

There are many components in gas boilers which are common to all types of systems and some which are only found in specific variations. The three primary components of the boiler as the gas valve, the combustion chamber, and the heat exchanger.

These three create the necessary conditions for using gas to boil water. Other components ensure the safe operation of the boiler and the effective flow of water around the system.

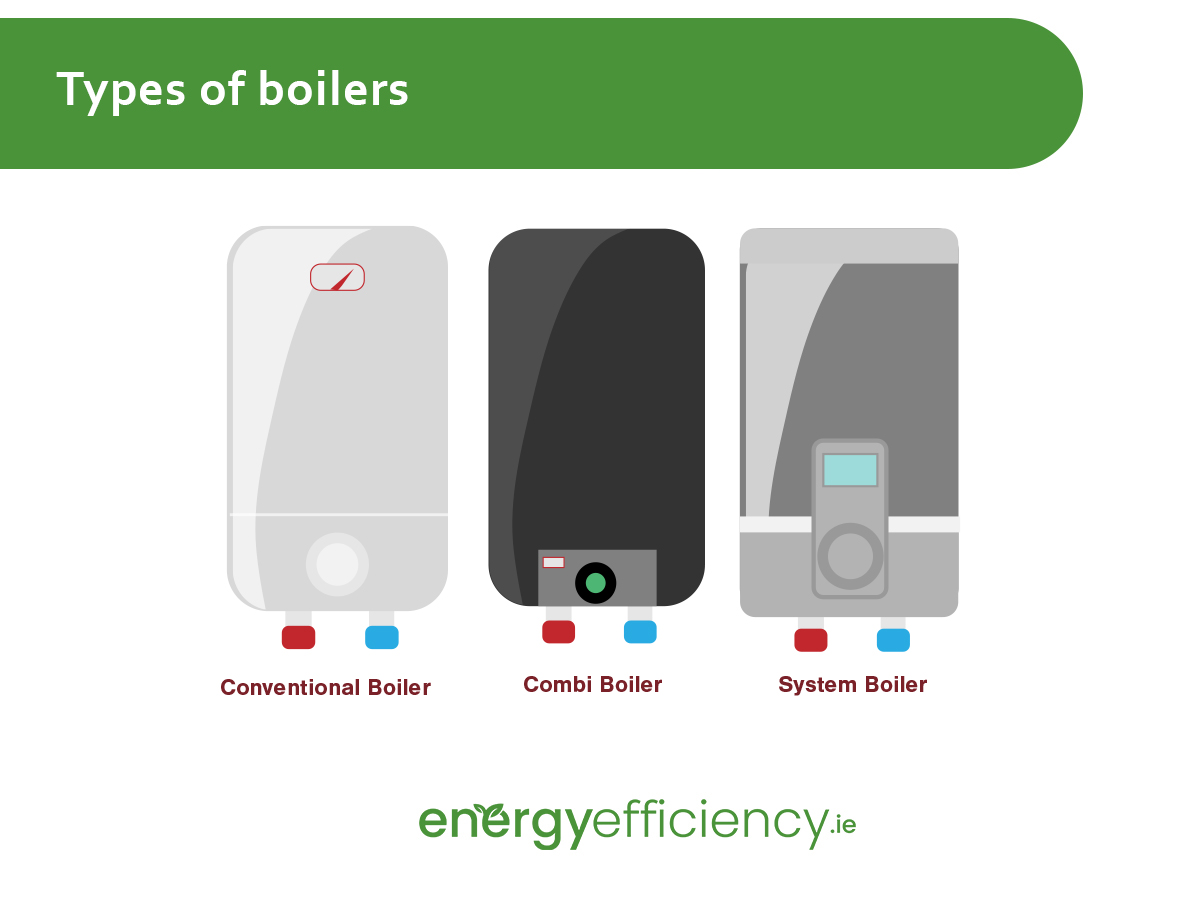

Types of Boilers

There are three main types of boilers separate from whether we are talking about gas, oil, electric, or biomass as a fuel source. These are:

All of them operate the same basic function of burning gas to heat water. The main differences between them are related to water storage methods.

Best Boiler Brands in Ireland

There are many brands of boilers in Ireland with differing strengths and weaknesses based on their cost, output size, system type, and warranties.

Customers should shop around to ensure they have the right boiler for their needs. Three of the most high-quality and popular brands in Ireland are:

How Long Do Gas Boilers Last

The average lifespan of a gas boiler before it needs replacement will be in the area of 15 – 20 years depending on the quality of the boiler. An entry-level boiler might start to wear out after as little as 10 years, so it is generally recommended to invest in a product which is better value in the long term.

Warranties for gas boilers will depend on the manufacturer and the system model, but most will be in the range of 8 – 12 years.

How Much Do Gas Boilers Cost

The average cost of a gas boiler for the majority of customers will be somewhere in the range of €1,500 – €3,500 based on the make and power output, typically up to around 35kW for this price range.

Larger boilers up to 50kW in output suitable for very large homes or businesses can cost in the region of €6,000.

There isn’t much difference between the cost of Combi Boilers and Traditional Boilers themselves. However, the Combi Boiler will have a lower installation cost, as it’s simpler to install without needing a water tank. They are also less likely to have maintenance issues with the simpler system.

Grants for Boilers

The SEAI used to have a grant for homeowners to upgrade to more energy efficient boilers. However, that has since been discontinued as the government is pushing for heat pumps to take on a greater role in home heating.

You can improve the efficiency of your central heating system by installing heating controls, for which the SEAI does have a grant. This €700 flat rate grant is available for all homeowners, including landlords, and any property occupied before 2011 is eligible.

Heating Control Systems can include Thermostatic Radiator Valves (TRVs) which regulate how much heat flows into individual radiatwors based on the desired temperature of the room.

7-Day Programmable Timer allows you to control how your home is heated daily and weekly to match when it is occupied. An Immersion Heater Time and Temperature Controls allow you to set when the immersion will come on, and the temperature it will heat the hot water cylinder to.

Signs It Is Time to Get a New Boiler

Once you know what the expected lifespan of a boiler is, there are signs that you should keep an eye out for that will let you know that it could be time to start looking for a replacement.

Oil Boiler v Gas Boiler

Oil Boilers and Gas Boilers are the two competing systems which still rely on burning fossil fuels for heat. Both systems have different strengths and weaknesses based on their convenience, energy efficiency, environmental performance, and costs.

Get a FREE Home Boiler Quote today

If you’re thinking of changing or replacing your boiler, take our assessment to get a free quote on what a new system will cost you.

Speak with Energy Efficiency today for a FREE quote!