Bifacial Solar Panels – All You Need to Know

Written by: Briain Kelly

Published: June 7, 2024

Last updated: October 16, 2025

Reading time: 4 mins

Improving the efficiency of solar panels is an ongoing process, with manufacturers constantly investing in new materials and technologies which will let them use as much solar energy as possible.

Bifacial solar panels are a type of PV module which captures sunlight on both their front and rear faces, increasing their efficiency and power output.

What are Bifacial Solar Modules

The premise behind Bifacial Solar Modules is simple, they produce power from both sides of the solar panel by having a transparent backsheet which allows reflected light to hit the solar cell on the rear side as well, increasing the efficiency of the solar panel.

This is different from traditional monofacial solar panels which have an opaque backsheet, and reflect unused light away from the module.

The majority of bifacial solar modules are manufactured using monocrystalline silicon and typically feature a slim profile, often designed without a typical frame.

Bifacial solar panels have the potential to increase the amount of power generated by solar PV by as much as 10-20% as the technology continues to improve.

How are Bifacial Solar Modules Used

Bifacial solar panels are highly dependent on the surface below them in order to generate power. They have their greatest potential in large-scale utility or commercial applications, where even a small increase in efficiency.

Flat roofs of factories or other large buildings could either be painted white or have a reflective foil surface laid down to improve the amount of light being reflected onto the back of the solar panels.

For solar farms in areas where snow cover is expected in Winter bifacial solar panels have the added advantage of gaining more power during the months where solar panels traditionally are at their lowest levels of production.

A three-year study by the National Renewable Energy Laboratory in the US found that bifacial solar panels which track the sun saw their greatest gains in efficiency during October, November, and December due to partial snow cover providing a more reflective surface on the ground.

Solar PV and Agriculture

Solar Panels have begun to gain traction for use on farms as a way for farmers to get the greatest use out of their land and generate additional income.

Ground-mounted solar panels can be placed at a height where the land can still easily be used for grazing by sheep, or panels can go on land which is otherwise proving unproductive.

Bifacial solar panels can greatly benefit when placed on farms in regions which are prone to snowfall in winter. The snow covering will make the land even more productive for solar panels at a time when it is of no use for grazing.

Free-Standing Solar Structures

Other areas where bifacial solar panels could potentially be of great use are free-standing ground-mounted structures such as solar carports.

Here they can provide shade and protection from the elements, as carports are meant to, while also creating solar energy. The cars themselves provide a more reflective surface for the light than the ground beneath them.

Residential Use of Bifacial Solar Panels

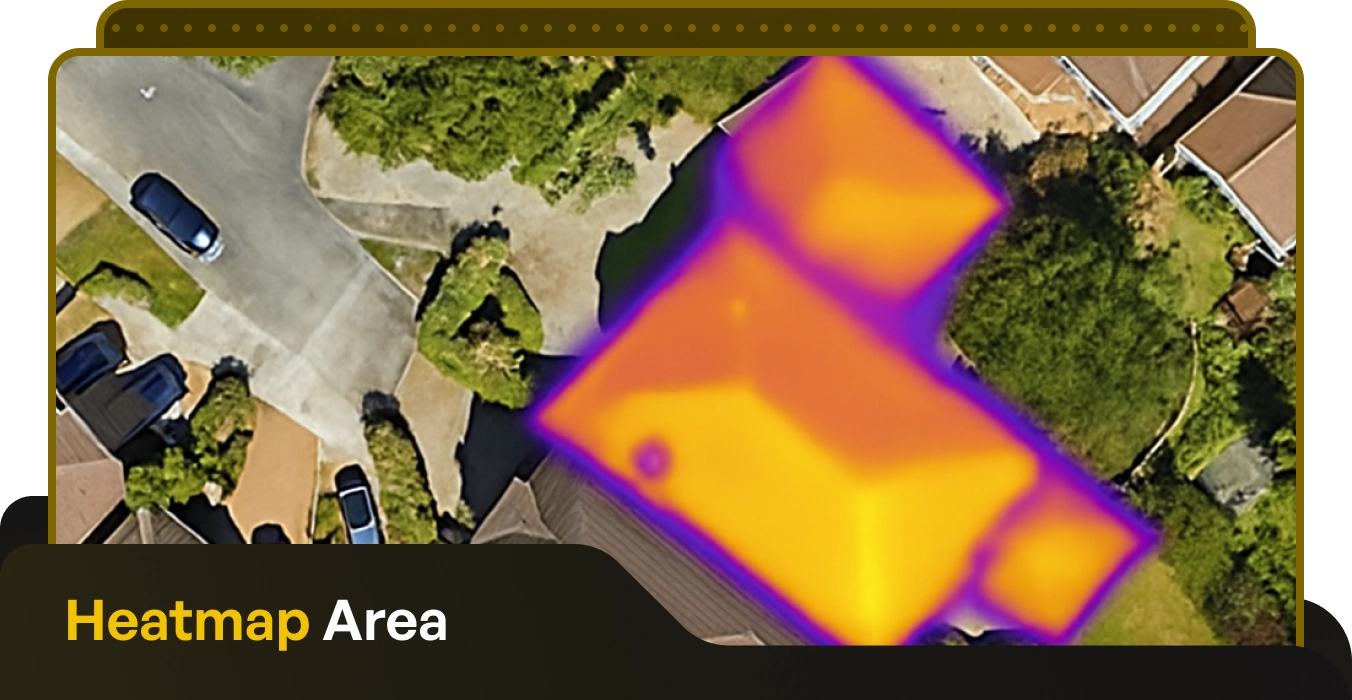

Bifacial solar panels will not deliver huge gains in the majority of domestic settings since they require a gap between the panels and the surface below them.

The vast majority of solar panels in residential use are installed on rooftops, almost completely flush with the roof surface. This leaves little to no room for any light to be reflected back at them

Colour is also an obstacle to the residential deployment of bifacial solar PV. As mentioned above bifacial panels work best with a light coloured or reflective surface below them. The majority of households have dark coloured roofs which absorb rather than reflect sunlight.

However, for homes and farms which have ground-mounted solar PV as opposed to rooftop installations, there is great potential for the use of bifacial solar panels.

Bifacial Solar Panels Brands

Bifacial solar panels are still far rarer than the monofacial panels which make up the majority of solar PV installations, but there are a number of companies which manufacture, some investing in a big way.

LONGi is perhaps the world’s largest manufacturer of bifacial solar panels, and is using the technology heavily in product lines such as the Hi-MO X6 and 7 series, with the X6 launching Bifacial Dual-Glass Modules this year.

The Jinko Solar Tiger series features options with bifacial technology such as the dual glass Tiger Neo N-type 78HL4-BDV.

Hyundai makes extensive use of bifacial modules for both utility and residential use with the OJ, OI, and YH series of modules.

Future Outlook of Bifacial Solar Panels

Though they might be suited for use on most households, bifacial solar panels will continue to expand their share of the marketplace in other areas.

Projections in the 15th annual International Technology Roadmap for Photovoltaics show that bifacial solar modules are expected to grow to more than 70% of world market share by 2034.

While the majority of bifacial solar modules are manufactured using silicon, work is already being done on creating solar cells using perovskite, the mineral which will likely replace silicon as the primary basis for solar panels in the next decade.

Challenges Facing Bifacial Solar PV

As with any new and emerging technology, there are challenges ahead for the widespread adoption of bifacial solar modules. One area of challenge is understanding how they will hold up over time.

Solar panels have decades long life expectancies in the field, and we don’t as yet have a full grasp of how bifacial modules will degrade over time compared with traditional monofacial solar panels.

The majority of bifacial solar panels are made with a glass-glass configuration for both the front and back of the panels. The greater weight of glass compared with traditional backsheets has led manufacturers toward working with thinner layers of glass on the panels.

This carries potential risks such as reduced structural integrity and potential greater susceptibility to hail impacts which need further study.

More research and testing are also needed on processes such as heat strengthening for thinner glass sheets as opposed to tempered glass, or on the use of transparent polymer backsheets as an alternative to glass-glass configurations.

One study found that there is not enough testing being done on how potential-induced degradation could affect the rear side of bifacial solar panels.

“Because unique potential-induced degradation mechanisms can occur on the back side of bifacial cells and modules, there is a need to develop potential-induced degradation tests specific to this configuration,” said Elizabeth Palmiotti, NREL materials scientist.

“Reliability research on the use of thinner glass—related to both hail impacts and structural integrity—as well as the use of mixed and coextruded encapsulants and transparent polymer backsheets would also be valuable.”

Bifacial Solar Panels – All You Need to Know

Published: June 7, 2024

Last updated: October 16, 2025

Written by: Briain Kelly

Reading time: 4mins

Improving the efficiency of solar panels is an ongoing process, with manufacturers constantly investing in new materials and technologies which will let them use as much solar energy as possible.

Bifacial solar panels are a type of PV module which captures sunlight on both their front and rear faces, increasing their efficiency and power output.

What are Bifacial Solar Modules

The premise behind Bifacial Solar Modules is simple, they produce power from both sides of the solar panel by having a transparent backsheet which allows reflected light to hit the solar cell on the rear side as well, increasing the efficiency of the solar panel.

This is different from traditional monofacial solar panels which have an opaque backsheet, and reflect unused light away from the module.

The majority of bifacial solar modules are manufactured using monocrystalline silicon and typically feature a slim profile, often designed without a typical frame.

Bifacial solar panels have the potential to increase the amount of power generated by solar PV by as much as 10-20% as the technology continues to improve.

How are Bifacial Solar Modules Used

Bifacial solar panels are highly dependent on the surface below them in order to generate power. They have their greatest potential in large-scale utility or commercial applications, where even a small increase in efficiency.

Flat roofs of factories or other large buildings could either be painted white or have a reflective foil surface laid down to improve the amount of light being reflected onto the back of the solar panels.

For solar farms in areas where snow cover is expected in Winter bifacial solar panels have the added advantage of gaining more power during the months where solar panels traditionally are at their lowest levels of production.

A three-year study by the National Renewable Energy Laboratory in the US found that bifacial solar panels which track the sun saw their greatest gains in efficiency during October, November, and December due to partial snow cover providing a more reflective surface on the ground.

Solar PV and Agriculture

Solar Panels have begun to gain traction for use on farms as a way for farmers to get the greatest use out of their land and generate additional income.

Ground-mounted solar panels can be placed at a height where the land can still easily be used for grazing by sheep, or panels can go on land which is otherwise proving unproductive.

Bifacial solar panels can greatly benefit when placed on farms in regions which are prone to snowfall in winter. The snow covering will make the land even more productive for solar panels at a time when it is of no use for grazing.

Free-Standing Solar Structures

Other areas where bifacial solar panels could potentially be of great use are free-standing ground-mounted structures such as solar carports.

Here they can provide shade and protection from the elements, as carports are meant to, while also creating solar energy. The cars themselves provide a more reflective surface for the light than the ground beneath them.

Residential Use of Bifacial Solar Panels

Bifacial solar panels will not deliver huge gains in the majority of domestic settings since they require a gap between the panels and the surface below them.

The vast majority of solar panels in residential use are installed on rooftops, almost completely flush with the roof surface. This leaves little to no room for any light to be reflected back at them

Colour is also an obstacle to the residential deployment of bifacial solar PV. As mentioned above bifacial panels work best with a light coloured or reflective surface below them. The majority of households have dark coloured roofs which absorb rather than reflect sunlight.

However, for homes and farms which have ground-mounted solar PV as opposed to rooftop installations, there is great potential for the use of bifacial solar panels.

Bifacial Solar Panels Brands

Bifacial solar panels are still far rarer than the monofacial panels which make up the majority of solar PV installations, but there are a number of companies which manufacture, some investing in a big way.

LONGi is perhaps the world’s largest manufacturer of bifacial solar panels, and is using the technology heavily in product lines such as the Hi-MO X6 and 7 series, with the X6 launching Bifacial Dual-Glass Modules this year.

The Jinko Solar Tiger series features options with bifacial technology such as the dual glass Tiger Neo N-type 78HL4-BDV.

Hyundai makes extensive use of bifacial modules for both utility and residential use with the OJ, OI, and YH series of modules.

Future Outlook of Bifacial Solar Panels

Though they might be suited for use on most households, bifacial solar panels will continue to expand their share of the marketplace in other areas.

Projections in the 15th annual International Technology Roadmap for Photovoltaics show that bifacial solar modules are expected to grow to more than 70% of world market share by 2034.

While the majority of bifacial solar modules are manufactured using silicon, work is already being done on creating solar cells using perovskite, the mineral which will likely replace silicon as the primary basis for solar panels in the next decade.

Challenges Facing Bifacial Solar PV

As with any new and emerging technology, there are challenges ahead for the widespread adoption of bifacial solar modules. One area of challenge is understanding how they will hold up over time.

Solar panels have decades long life expectancies in the field, and we don’t as yet have a full grasp of how bifacial modules will degrade over time compared with traditional monofacial solar panels.

The majority of bifacial solar panels are made with a glass-glass configuration for both the front and back of the panels. The greater weight of glass compared with traditional backsheets has led manufacturers toward working with thinner layers of glass on the panels.

This carries potential risks such as reduced structural integrity and potential greater susceptibility to hail impacts which need further study.

More research and testing are also needed on processes such as heat strengthening for thinner glass sheets as opposed to tempered glass, or on the use of transparent polymer backsheets as an alternative to glass-glass configurations.

One study found that there is not enough testing being done on how potential-induced degradation could affect the rear side of bifacial solar panels.

“Because unique potential-induced degradation mechanisms can occur on the back side of bifacial cells and modules, there is a need to develop potential-induced degradation tests specific to this configuration,” said Elizabeth Palmiotti, NREL materials scientist.

“Reliability research on the use of thinner glass—related to both hail impacts and structural integrity—as well as the use of mixed and coextruded encapsulants and transparent polymer backsheets would also be valuable.”

Solar Energy Saves Households Thousands in Electricity Costs

Take our 2-minute questionnaire and find affordable solar options to suit your budget and lifestyle.